Holte RC Drill Pipe

Field Proven Around the Globe

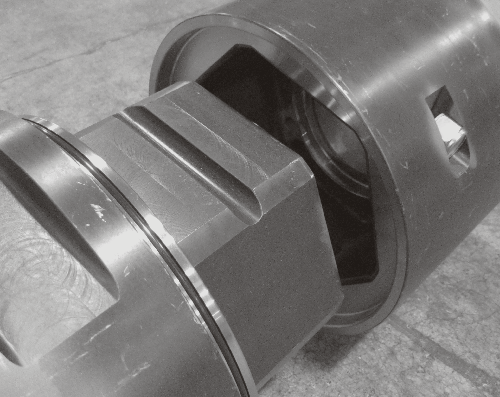

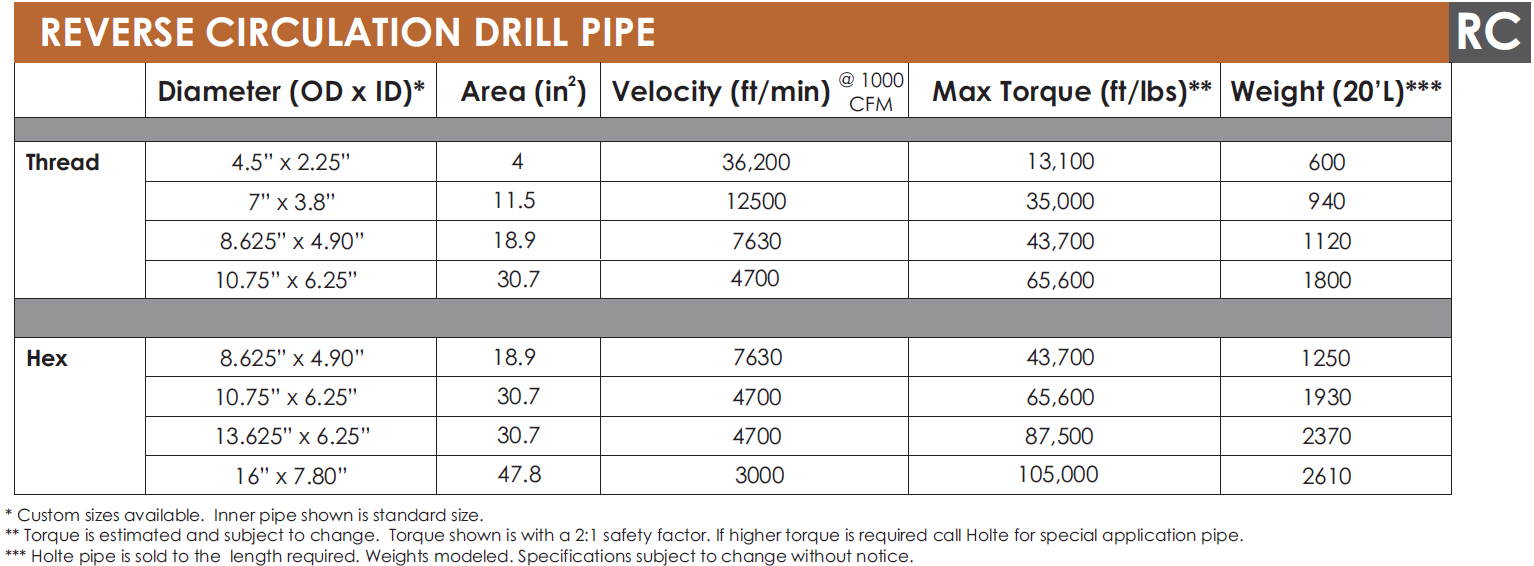

As an early proponent of RC drilling, Holte has remained dedicated to developing new ways to continually improve RC drill pipe design and manufacturing techniques. Holte produces traditional threaded and Hex Drive joints. We developed the original patent for Dual Wall Hex joint RC drill pipe. To ensure the highest quality, and balance of durability vs. hardness, Holte runs a dedicated Heat Treat facility.

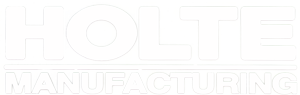

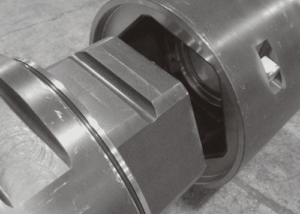

Holte’s standard RC dual wall pipe allows for air to move through the annulus between the center tube and the outer pipe, while the cuttings flow freely up through the center. Airflow channels are designed for optimum efficiency and to be matched to Holte DHHs and Top Heads.

Simplicity, Durability, and Expert Design

Our expertise in understanding materials and the strains placed on them during drilling derives from our years of manufacturing and working in the field alongside our customers. Precision machined tool joints and pipe are carburized during heat treatment for additional hardness. Prior to welding the outer pipe to the joints, we carefully torque the inner pipe into the machined joint, creating additional strength.

Over 45 years has led to ingrained RC expertise. Our founder, Art Holte, remains one of the most gifted innovators and experts in the field of Reverse Circulation Drilling technology. Art’s emphasis on comprehension of the complete RC drilling system, and a relentless standard to make high quality tooling, have pervaded the company. We grow with the needs of the industry—not shareholders. Our sales and design teams have literally machined, assembled, and used RC drills. We’ve modified drill rigs to work with Reverse Circulation. Our offices are still on the manufacturing floor where we can hear the sweet sounds of CNCs and testing hammers; where machinists, sales, and designers can interact to make sure our drilling tools lead the industry.