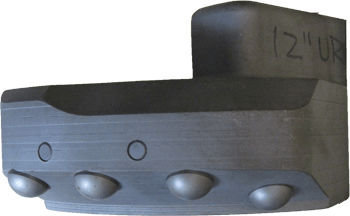

Underreamer Gauge (URG)

- Underream on all sides of the hole simultaneously with a wing bit system.

- More contact surface than other underreamers results in faster penetration.

- 360° concentric underreaming results in straighter holes than eccentric underreaming.

- Low cost replaceable Arms extend the life of the system.

- Available in RC or Conventional in a variety of Shank styles.

- Tapered Arms and 30° reverse rotation retract the arms without risk of unthreading pipe.

- Less moving parts, bigger arms, and simpler operation than other retractable style underreamers.

- Wears slower than eccentric style (eccentric only reams 50% of the hole at a time).

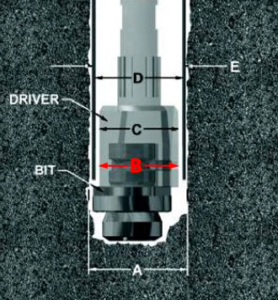

The Holte URG® (Underreamer Gauge) Underreamer has an extendible arm bit (wing bit) and is considered superior to a one-sided UR because three (3) to four (4) arms extend to ream a full gauge (360 degree) hole. The underreamers which swing out on only one side drill slower and not always straight.

This bit design was developed at Holte Manufacturing while researching faster ways to drill large diameter holes. Because there is bit surface reaming the full gauge of the hole, this bit wears much better than an eccentric style bit which only reams with about a 50 degree portion of the hole.

The Full Gauge UR resembles a conventional hole opener. The extendible arms cover 360 degrees of the hole circumference, minus three air slots, similar in size to a conventional bit. We offer URG Overburden Systems between 10″ – 42″ configured with three (3) or four (4) arms for both conventional and reverse circulation drilling.

Options and Features

- RC cuttings evacuation hole is off-center in pilot bit to minimize plugging.

- Variety of shank styles and sizes: IR, Mission, QL, and Holte.

- Use with a Casing Hammer or Drive Shoes.

- Replaceable Pilot Bit.

- Retaining Pin design permits quick and easy changing of the Arms.

- Carbide or Diamond Buttons.

- RC acts like jetting sub (lift and it sucks the whole clean).

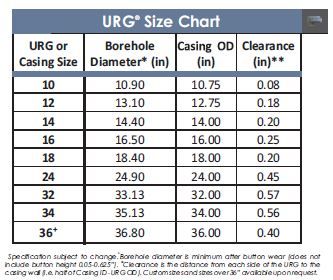

URGs® come in a variety of sizes. They can be customized for non-standard casing

or to meet special borehole diameter needs and applications.

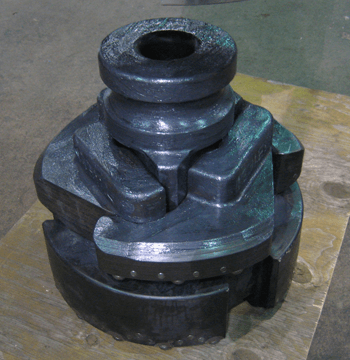

Underreamer Gauge URG Casing Driver Style

Underreamer Gauge with Casing Driver

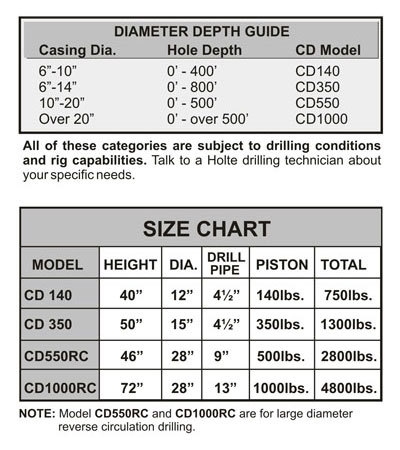

The Holte Casing Driver (CD) was designed to be small and compact as well as hard hitting like a Down Hole Hammer (DHH). While the CD cycles fast like a DHH and is designed around a much larger piston since it is above ground. Delivering an extremely powerful impact for driving casing. This allows your DHH to run most efficiently since its energy is not absorbed trying to pull casing along with it.

The Holte Casing Driver is designed to be used with a DHH and underreamer. It is available in four sizes. Easily portable sizes for light duty rigs to a heavy duty size for the most extreme well and hole conditions.

The casing drive acts similar to a down hole hammer. When the hole is first started, the casing driver sits inactive on the casing acting as a water diverter. When the underreamer advances 1” ahead of the casing the anvil closes and the driver starts operating. The more the anvil is closed, the harder the casing driver hits. The CD turns on and off automatically and runs only when the casing lags behind the underreamer, causing the anvil to close. There is only 1 1/4” of vertical movement of the CD anvil so the casing will always remain within 3” of the bit.

Casing Driver Charts

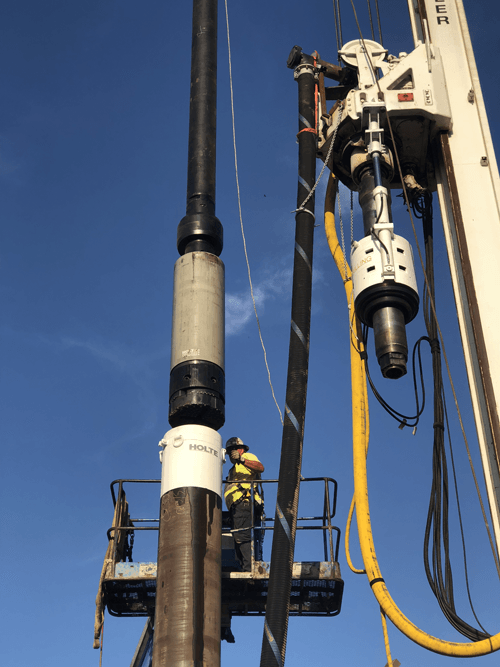

Underreamer Gauge URG drive shoe style

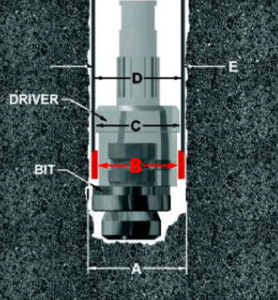

Maximize your underreaming with a Holte URG designed to have a wider cutting edge where you need it most. The Holte extendible arms underreams 360 degrees of the bore hole wall. The URG Drive Shoe Style Underreamer driver portion has a drive shoulder. The shoulder drives down the drive shoe that is welded to the casing. Using the URG, the down hole hammer is used to both drill and drive casing.

Drive Shoe