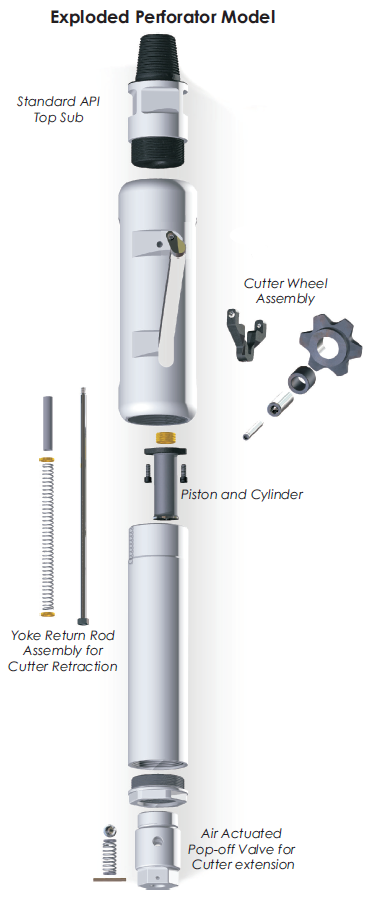

How a Perforator Works

Designed for use with Rotary Drills, the HOLTE Perforator threads onto a standard Drill String. Either through knowledge of water depth, or watching the cuttings for tell-tale signs like water, gravel, or sand, the Perforator can be lowered to the exact depth of the aquifer.

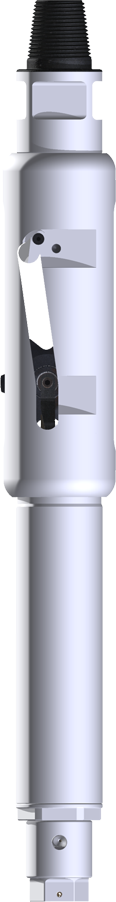

Applying a small amount of air pressure (90 PSI, any CFM) the Perforator Cutting Wheel extends and bites into the Casing wall. As the Rig pushes the Perforator down the Casing pulls the Cutter out fully (after ~6” of travel) and the Perforator starts punching holes in the casing that are about 1” long, 0.25” wide, and spaced about 1.5” apart.

After quickly perforating a column, the Drill String is returned to the starting location, air is turned off to retract the Cutter, then the String is rotated to start the next column of perforations. Good practice is to put a column in about every 4-5 inches around the Casing diameter—about 4 or 5 columns for 6” Casing.

For Casing sized larger than the Perforator, Slide or Roller Adapters are available for Casing up to 24″. Custom Adapters can be provided for odd sizes, special jobs, and for sizes even bigger than 24”. Smaller diameter pipe provides less friction for perforating with Slide Adapters. Roller Adapters reduce the force needed by about 25% so perforation can be done with smaller Rigs and Rollers work best for larger diameter pipes.