When working in construction and thinking about drilling for foundation, oftentimes we use Reverse Circulation due to the heavily regulated areas that construction is being done in. In Foundation and Construction Drilling, RC systems are also able to be used in partnership with other technologies. Holte’s Grout Through Technology for secant walls is a common technology to use in tandem with RC systems.

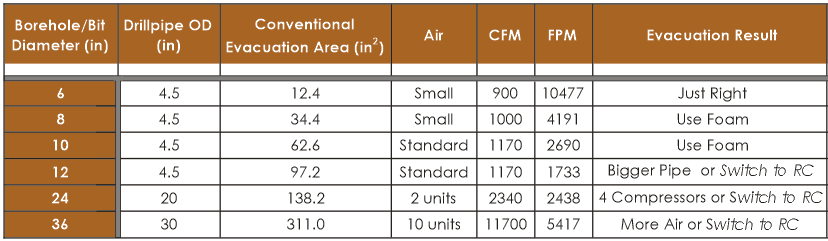

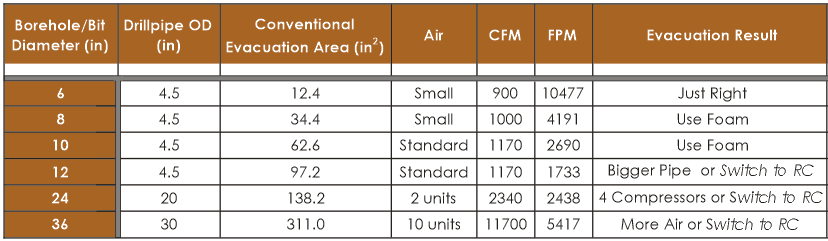

Both Conventional Drilling and Reverse Circulation Drilling are used in the Water Well Industry. Conventional is used more often for most wells. If a well is large (16 inches or more) or has some unconventional requirements, a RC system may be useful to help speed up your project. RC is also great for unstable ground conditions, where blowing rocks up the hole might cause it to cave in.

When exploring something new, you may want to be able to examine your cuttings that are coming from the hole you are drilling. Reverse Circulation Drilling is a great option to investigate the cuttings because you can control where they are discharged. When paired with a cyclone, silt sifter, or an archeologist, discharge can be reused or explored!

Leave A Comment